Our end-to-end Power Management System fuses proprietary, ML-integrated smart hardware with advanced edge computing and AI-driven analytics to deliver precise, real-time monitoring, dynamic load balancing, and predictive maintenance—empowering you to reduce costs, enhance safety, and future-proof your operations.

.png)

Transform your facility into a resilient, proactive power ecosystem. Evoluzn’s pioneering ML and Edge technologies empower you to predict risks, enhance operational efficiency, and secure your industrial future.

✔ Maintains uninterrupted power quality to protect sensitive servers and data storage hardware.

✔ Supports load balancing to reduce peak power costs and improve energy efficiency.

✔ Ensures uninterrupted power quality that is critical for sensitive manufacturing processes.

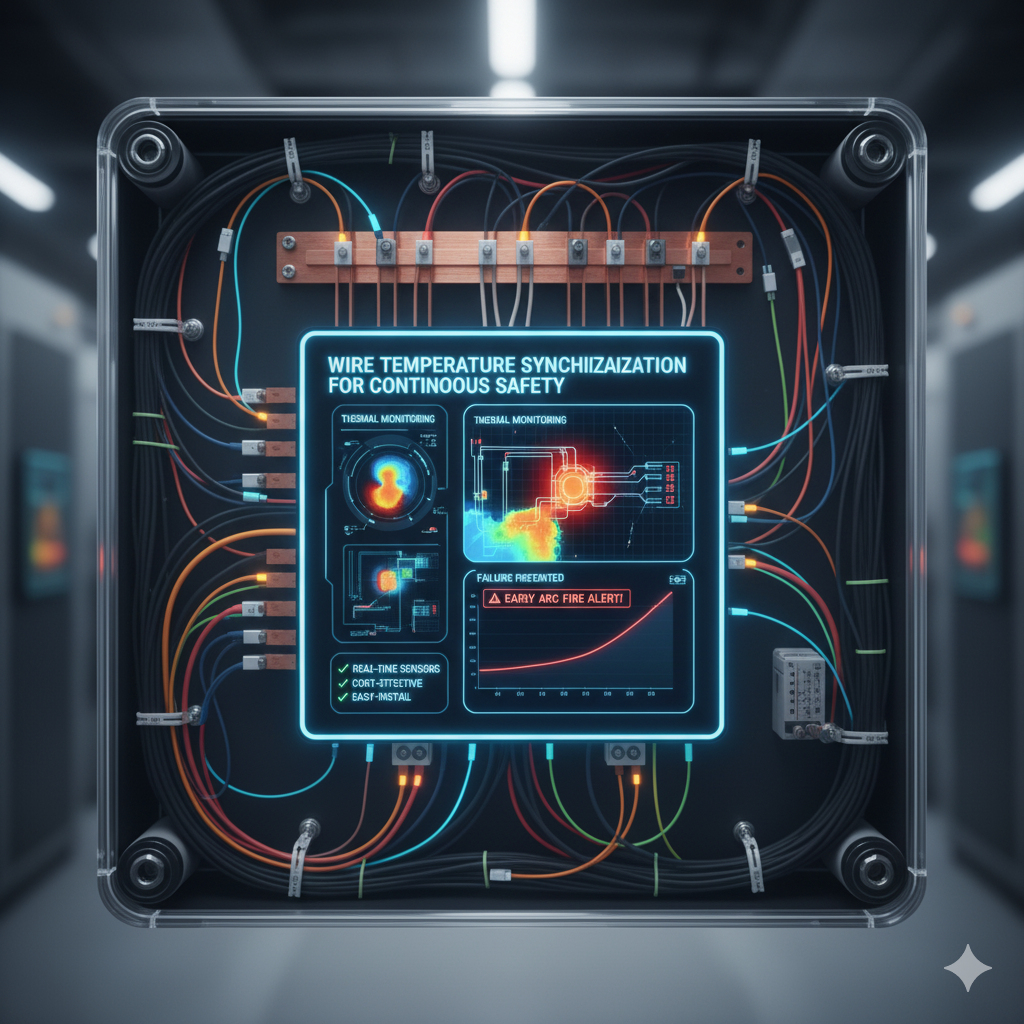

✔ Real-time load and thermal monitoring prevent costly equipment failures and support stringent safety standards.

✔ Maintains ultra-stable power quality critical for defect-free chip fabrication and high yield.

✔ Enables predictive maintenance to avoid costly downtime and equipment damage, supporting tight production schedules.

✔ Precise thermal and load control safeguards against fire hazards and equipment degradation.

✔ Edge computing enables rapid detection of anomalies in critical energy-intensive processes.

✔ Advanced power quality analysis and fault detection reduce downtime in delicate assembly lines.

✔ Automated load balancing improves energy efficiency and protects sensitive electronic devices.

✔ Dynamic load management supports complex assembly operations and reduces peak demand charges.

✔Real-time alerts and centralized control enhance operational safety across diverse power loads.

✔ Enhances safety by continuous monitoring of power loads in hazardous environments, preventing electrical faults and explosions.

✔ Optimizes energy consumption in high-demand chemical processes, reducing operational costs and environmental impact.

✔ Ensures reliable power for refrigeration and processing equipment, maintaining product safety and quality.

✔ Reduces energy waste through dynamic load management, supporting sustainability and cost savings.

✔ Provides robust protection for heavy machinery via real-time thermal and load monitoring.

✔ Improves operational continuity by preventing overloads and enabling predictive maintenance.

✔ Prevents power fluctuations that could compromise temperature-sensitive storage.

✔ Enables scalable monitoring and control for energy savings and operational reliability.

✔ Scalable power monitoring adapts to growing production lines and varied load demands.

✔Predictive maintenance minimizes costly stoppages in fast-paced manufacturing environments.

✔ Optimizes distributed power management for improved efficiency and grid stability.

✔ Supports integration of diverse energy sources with intelligent load balancing and fault detection.